Generator work is an essential skill for anyone who needs to keep their home powered. Whether you’re dealing with a prolonged power outage or just want to be prepared in case of an emergency, understanding the basics of generator work can help you keep your home running. In this article, we’ll discuss the basics of generator work, including the types of generators available, how to select the right one for your needs, and how to safely operate a generator.

What is a Generator?

A generator is an electrical device that converts mechanical energy into electrical energy. It works by using a rotating coil of wire to create a magnetic field, which then induces a current in a secondary coil of wire. This current is used to generate electricity. Generators are used in a variety of applications, including in power plants, in ships, and in emergency power supplies. They are also used to provide power to remote locations where power lines do not reach. Generators are typically powered by gasoline, diesel, or natural gas, although other sources of fuel can be used. They can be small enough to fit in a person’s hand, or large enough to power an entire city.

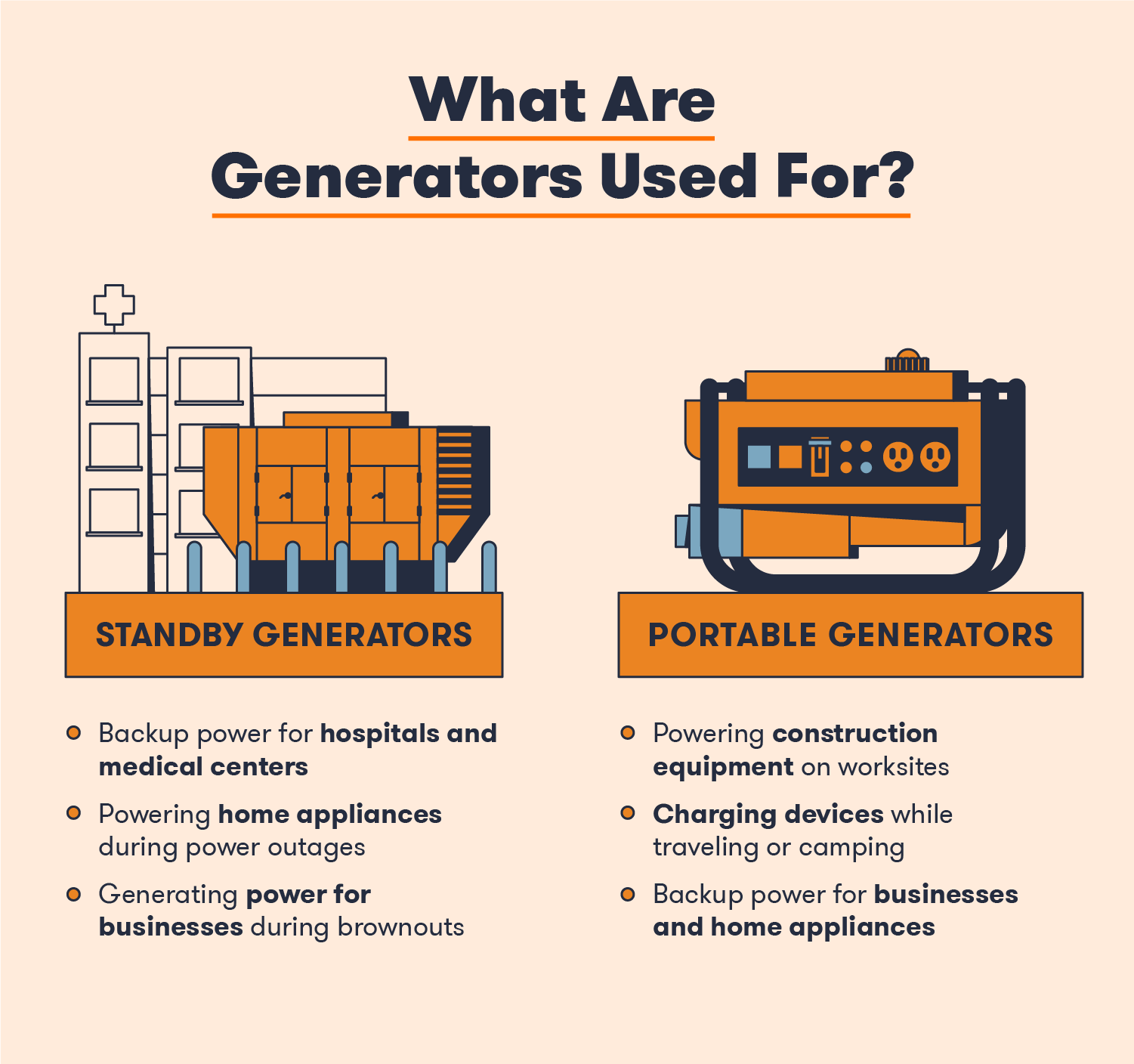

Portable Generators

Portable generators are small and lightweight power sources typically used for emergency, recreational, and work site applications. These generators are great for powering small tools and appliances, and are easily transported and stored.

Standby Generators

Standby generators are permanently connected to your home and provide a reliable backup power source in the event of a power outage. Unlike portable generators, standby generators are larger and require professional installation.

Industrial Generators

Industrial generators are large, powerful and designed for heavy-duty industrial applications such as powering entire factories or businesses. These generators are designed to run for extended periods of time and can produce large amounts of electricity.

Working Principle

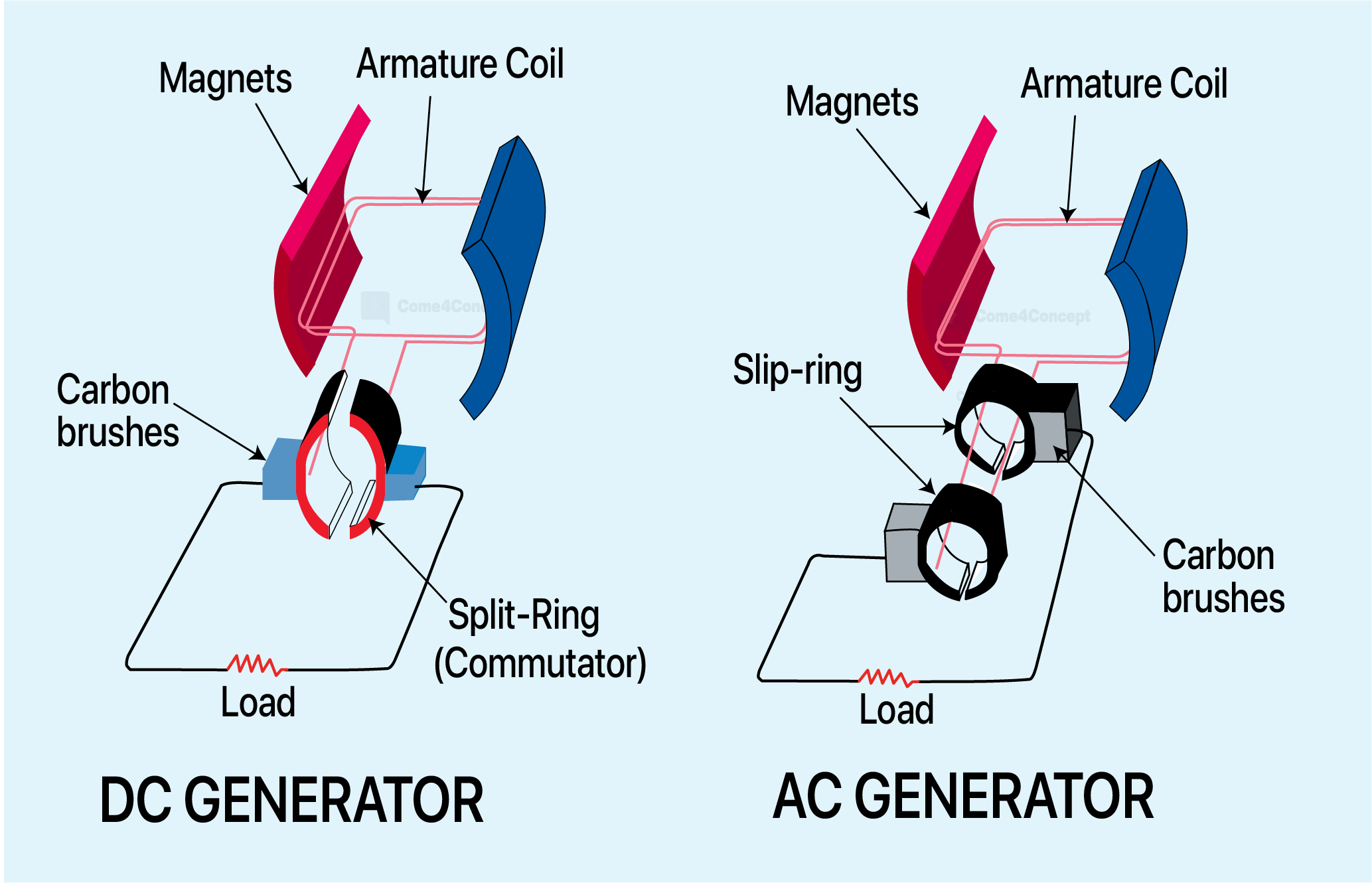

Generators produce electricity by converting mechanical energy into electrical energy. The majority of generators have engines that run on a combustible fuel such as gasoline, diesel, propane, or natural gas. The engine turns a generator shaft that is connected to a series of magnets. As the shaft turns, the magnets create a changing magnetic field that induces an electric current in the generator’s windings.

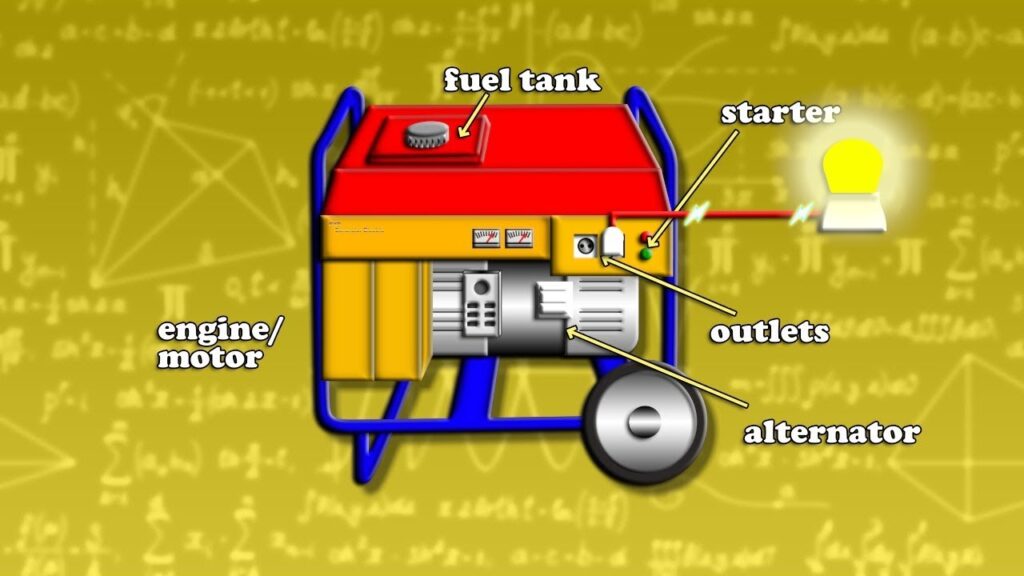

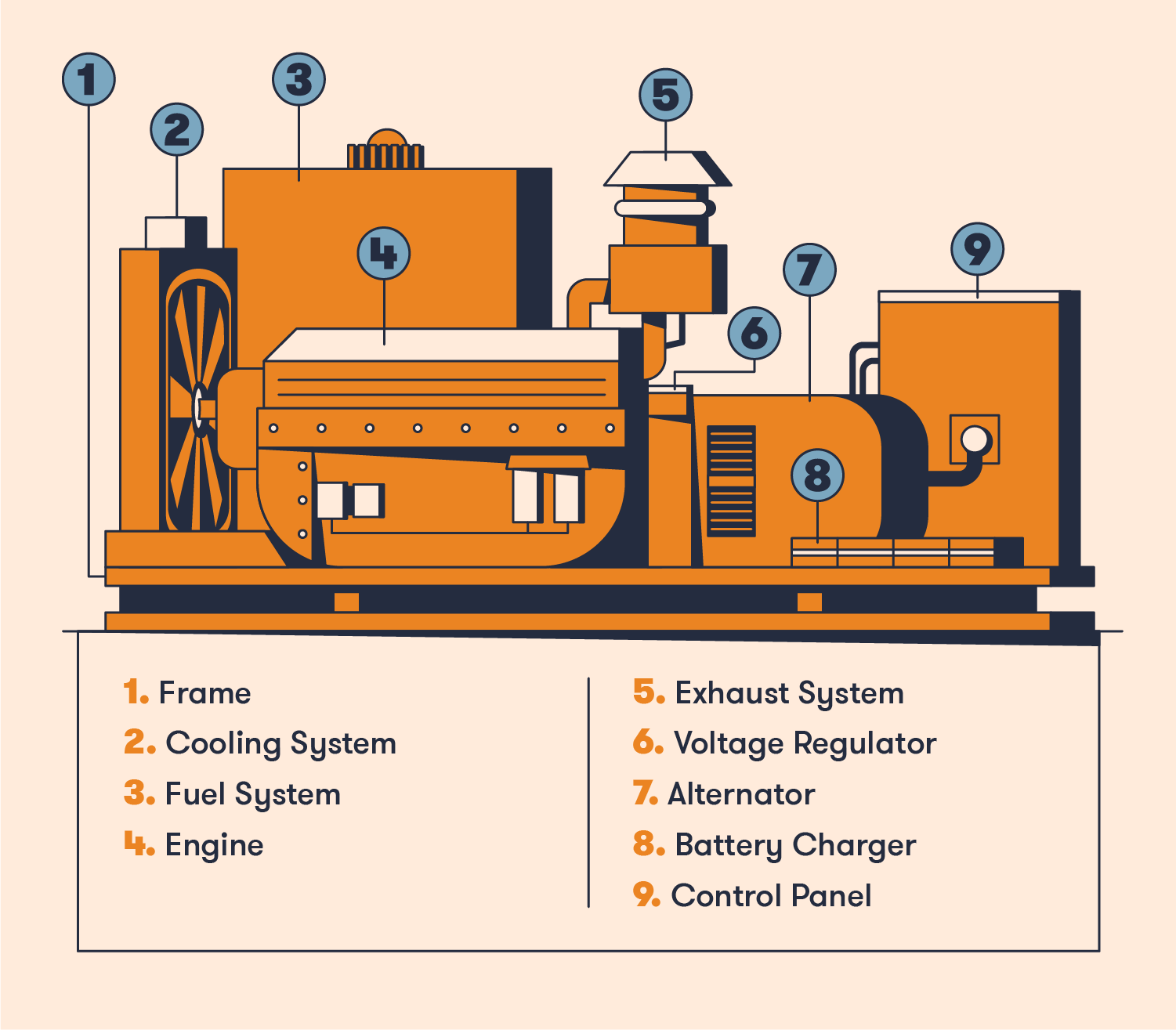

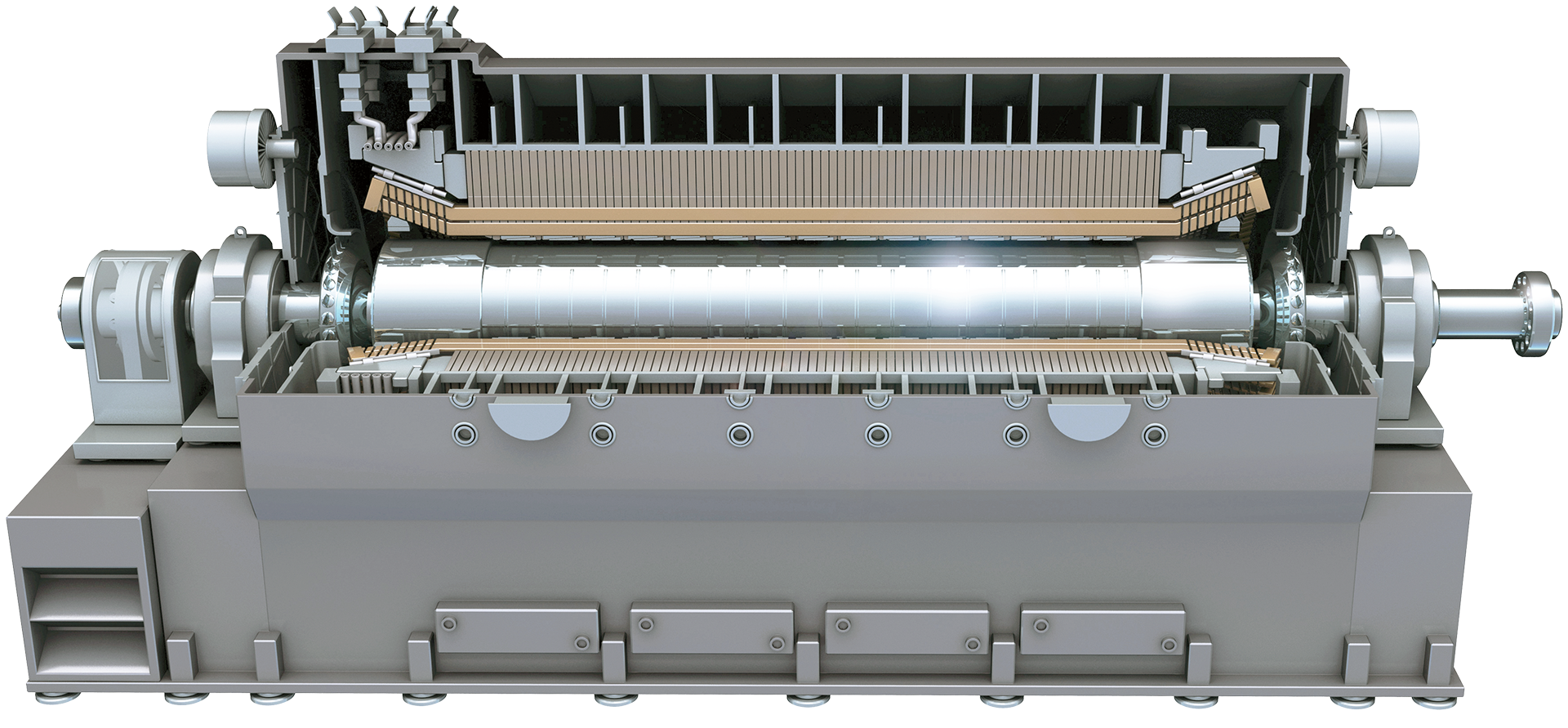

Generator Components

Generators consist of several main components, including the engine, alternator, excitation system, voltage regulator, cooling system, fuel system, and exhaust system. The engine is the heart of the generator and is responsible for converting the fuel into mechanical energy. The alternator is the component that actually generates the electricity and is connected to the engine by the generator shaft. The excitation system is responsible for providing the voltage needed to create the changing magnetic field in the alternator. The voltage regulator is responsible for ensuring that the voltage output of the generator is consistent. The cooling system is needed to keep the engine from overheating. The fuel system is responsible for supplying the needed fuel to the engine. The exhaust system is needed to safely vent gases created by the combustion process.

Generator Output

The output of the generator is measured in watts. The wattage produced by a generator is determined by the size and type of engine used, as well as the alternator used. Generators can produce AC or DC power. AC power is used for most household appliances and is the standard form of electrical power. DC power is used for some specialty applications such as powering an electric vehicle.

Generator Maintenance

| Maintenance | Frequency |

|---|---|

| Check oil level and add as necessary | Weekly |

| Check coolant levels and add as necessary | Monthly |

| Check battery voltage and charge as necessary | Monthly |

| Check air filters and clean or replace as necessary | Monthly |

| Check spark plugs and replace as necessary | Every 2 years |

| Check fuel filters and replace as necessary | Every 2 years |

| Check engine mounts and replace as necessary | Every 2 years |

| Check exhaust system and repair as necessary | Every 2 years |

| Check generator bearings and replace as necessary | Every 5 years |

| Check control panel and wiring and repair as necessary | Every 5 years |

| Check alternator and replace as necessary | Every 5 years |

Regular maintenance of a generator is essential to ensure reliable service and to reduce the risk of breakdowns. The following is a list of maintenance tasks that should be performed on a regular basis, as well as the recommended frequency.

1. Regular Maintenance

- Check the oil level and top up as necessary.

- Check the fuel level, top up and check for water contamination.

- Check the air filters, clean or replace if necessary.

- Check the spark plugs, clean or replace if necessary.

- Check the battery, clean and/or replace if necessary.

- Clean the fuel tank and fuel lines.

- Check the cooling system, clean and/or replace any worn or damaged parts.

- Check all wiring and connections, clean and repair any damaged connections.

- Check the exhaust system, clean and/or replace any worn or damaged parts.

2. Troubleshooting

- Check if the fuel supply is blocked.

- Check if the fuel filter is clogged.

- Ensure that the voltage regulator is functioning correctly.

- Check if the air filter is clogged.

- Check if the air intake is blocked.

- Ensure that the spark plugs are clean and in good condition.

- Check if the battery is charged.

- Check if the generator is producing enough electricity.

- Check if the alternator belt is too loose.

- Check if the alternator is functioning correctly.

- Check if the generator is grounding correctly.

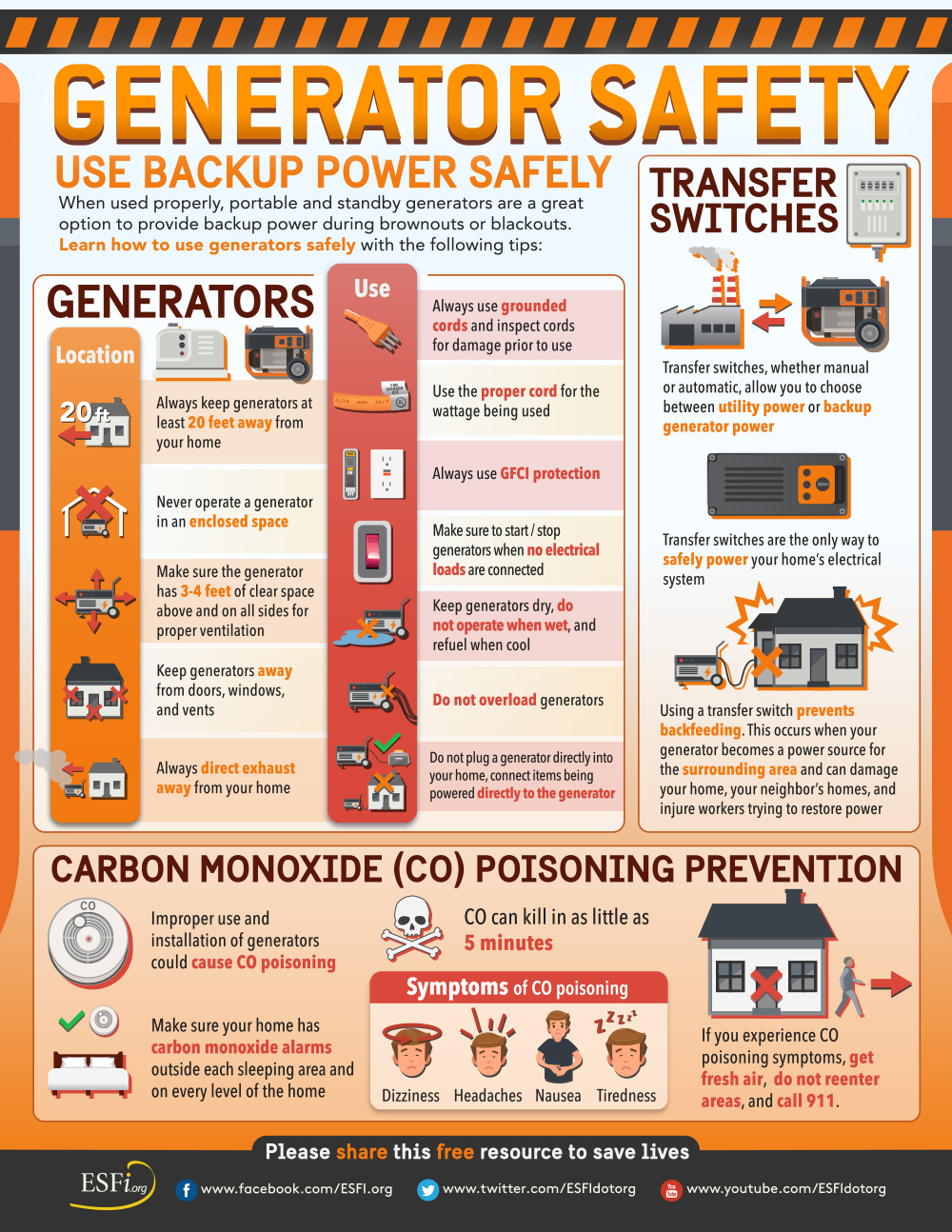

Generator Safety

| Task | Safety Measure |

|---|---|

| Installing a generator | Refer to manufacturer’s installation instructions and/or hire a qualified electrician. |

| Operation | Never operate a generator inside an enclosed space, including basements and garages. Operate it in a well-ventilated, dry area outdoors, away from windows, doors, and vents. |

| Refueling | Allow the engine to cool down before refueling. Do not smoke while refueling and use an approved, spill-proof container. |

| Electrical Cords | Do not overload circuits and use the correct gauge extension cords. Make sure all cords are in good condition and rated to handle the load. |

| Storage | Store fuel in approved, labeled containers and store generator in a dry and secure place. |

1. Installation

| Step | Instructions |

|---|---|

| 1 | Place the generator onto a level surface. |

| 2 | Plug the generator into a power source. |

| 3 | Fill the generator with oil. |

| 4 | Attach the exhaust pipe. |

| 5 | Attach the fuel line. |

| 6 | Pull the starter cord to start the generator. |

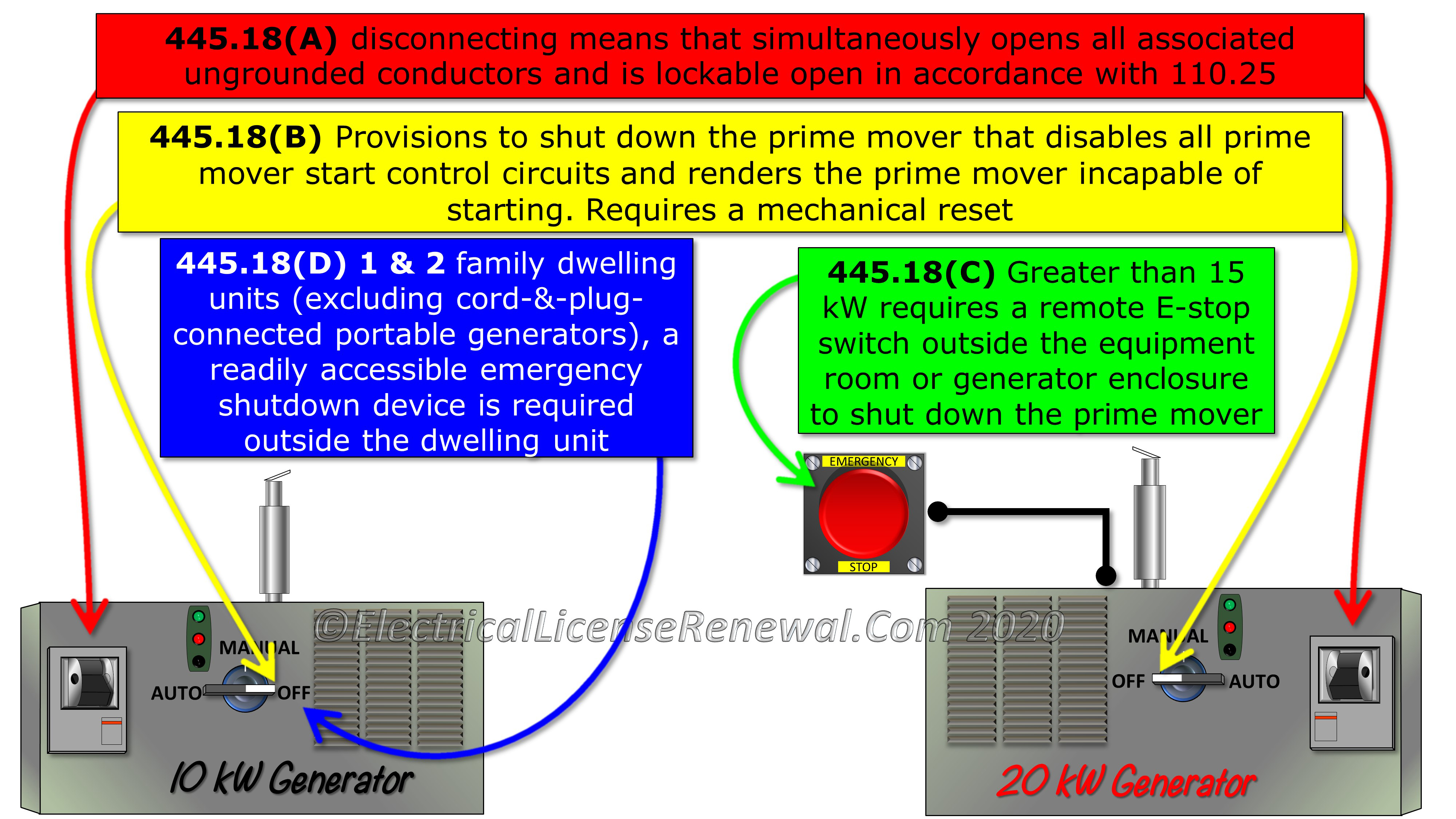

2. Emergency Shut-Down

- Identify the emergency shut-down procedure for the generator.

- Familiarize yourself with the emergency stop buttons and/or controls.

- Know the location of the emergency stop buttons and/or controls.

- Know how to use the emergency stop buttons and/or controls.

- Know the consequences of not using the emergency stop buttons and/or controls.

- In the event of an emergency, shut down the generator immediately by pushing the emergency stop buttons and/or controls.

- Check the generator and its surroundings after an emergency shut down.

- Inspect the generator for any damage or malfunction.

- Repair or replace any damaged or malfunctioning parts of the generator.

Generator Efficiency

- Generator efficiency is defined as the ratio of the electrical energy produced by the generator to the energy supplied to it in the form of fuel.

- Generators are rated in terms of their efficiency when operating at a particular load level and speed.

- When the load on the generator increases, its efficiency decreases and vice versa.

- The efficiency of a generator can be improved by increasing the speed of the generator and by using advanced technologies such as variable speed drives.

- The efficiency of a generator also depends on the type of fuel used and the ambient temperature.

- Generator efficiency can be improved by using high efficiency components such as transformers, alternators, and other electrical components.

- Generator maintenance and proper operation can also help in increasing the efficiency of the generator.

1. Fuel Efficiency

- Generators operate most efficiently when they have a consistent load.

- Utilizing fuel efficiently is a key factor in the overall cost of operation.

- Many generators have optional fuel efficiency features such as auto-idle control and variable speed operation.

- Auto-idle control automatically reduces engine speed when the load on the generator is low, saving fuel.

- Variable speed operation allows the engine to adjust its speed to the current load, using only the fuel needed to meet the load.

- Regular maintenance and tune-ups are also important for maximizing fuel efficiency.

2. Efficiency Rating

Generator work efficiency is represented by a percentage rating, which is determined by the total power output of the generator divided by the total power input. This efficiency rating is known as the “Generator Efficiency Rating” or GER.

| Input | Output |

|---|---|

| Power Input | Power Output |

| 100kW | 90kW |

The GER for this generator would be 90% (90kW/100kW). The GER for a generator is dependent on the type of generator and the load it is running. The higher the load that the generator is running, the lower the GER will be.

Generator Technologies

Generators can be powered by a variety of sources, including gasoline, diesel, natural gas, and propane. The type of fuel used depends on the application and the size of the generator. Generators come in a variety of sizes, ranging from small portable units to large industrial-sized units. The size and type of generator used will depend on the power needs of the application.

Generators may use a variety of technologies to produce electricity. These technologies include traditional combustion engines, which use mechanical energy to generate electricity, as well as more advanced technologies like steam turbines, which use thermal energy to generate electricity. Generators may also use renewable energy sources such as wind, solar, and hydro power.

Generators may also use advanced technologies such as fuel cells, which directly convert chemical energy into electricity without the use of a combustion engine. Generators may also use inverters, which convert direct current (DC) into alternating current (AC). Generators may also use synchronous generators, which are connected to an AC power source and supply power to a load.

1. Conventional Generators

Conventional generators are electro-mechanical devices that convert mechanical energy into electrical energy. This is done by using a rotating shaft to produce a magnetic field within the generator. The magnetic field then induces an electrical current in the coils of wire that make up the generator’s stator. The current is then carried to an external circuit where it is used to power electrical equipment. The generator works by transferring the mechanical energy from the rotating shaft to the stator, which then produces an electrical current. This type of generator is typically used in stationary applications such as power plants, as well as in mobile applications such as cars and boats.

2. Alternative Generators

Generators come in a variety of types and designs, depending on the intended use. Alternative generator designs can be used to create electricity, mechanical power, and cooling or heating.

Fuel Cells

Fuel cells generate electricity through a chemical reaction that combines oxygen and hydrogen. Fuel cells are used in applications where a clean, continuous, and reliable source of electricity is required, such as in electric vehicles, stationary power plants, or as a backup power source.

Solar Panels

Solar panels, or photovoltaic cells, generate electricity directly from sunlight. Solar cells are often used in remote locations where grid access is not available, or to supplement existing electricity grids.

Wind Turbines

Wind turbines generate electricity by harnessing the power of the wind. Wind turbines are commonly used to supplement existing power grids or in remote locations.

Microturbines

Microturbines are a type of small turbine engine that can be used to generate electricity, mechanical power, and cooling or heating. Microturbines are usually used in applications that require a consistent and reliable source of power, such as in remote locations or as a backup power source.

Geothermal Power Plants

Geothermal power plants use heat from the Earth’s core to generate electricity. Geothermal power plants are usually built in areas where there is a large concentration of geothermal energy, such as near volcanoes or hot springs.

Frequently Asked Questions

What is a power generator?

A power generator is a device that converts mechanical energy into electrical energy. It works by using an engine to rotate a shaft, which in turn spins an alternator that produces electrical power. Generators can be used to provide electricity in areas where there is no access to the power grid, as well as for backup power in case of an emergency.

How does a Generator Work?

A generator is a machine that converts mechanical energy into electrical energy. It does this by using a rotating magnetic field to produce an electric current. Generators can be used in a variety of applications, including providing power to residential and industrial buildings, powering portable electrical devices, and providing emergency power. Generators typically use an internal combustion engine, turbine, or other type of engine to drive the generator’s alternator and produce electricity. The alternator is the device that converts mechanical energy into electrical energy, and it typically consists of a rotating armature and a stationary field. As the engine spins the alternator, it creates a magnetic field that induces an electric current, which is then sent to the generator’s power outlets.

What is the Operation of a Generator?

A generator is a machine that converts mechanical energy into electrical energy. It works by using an engine to rotate an alternator, which in turn produces AC electrical power. The engine can be powered by diesel, gasoline, propane, natural gas, or a variety of other fuel sources. The alternator is then connected to a transformer, which converts the AC power into DC power suitable for powering electrical devices.

How Can I Keep My Home Powered with a Generator?

A generator is a device that converts mechanical energy into electrical energy. It is commonly used as a backup power source for homes, businesses, and other facilities in the event of a power outage. To keep your home powered with a generator, you need to select the right size and type for your needs and install it correctly. The generator should be sized to handle the power load of your home, and the installation should follow the manufacturer’s instructions and local codes. You should also make sure to regularly maintain and service the generator to ensure it runs safely and efficiently.

What are the Basics of Generator Work?

Generators are machines that convert mechanical energy into electrical energy. The mechanical energy can come from sources such as an internal combustion engine, wind turbines, or hand-cranked generators. Generators work by using a magnet and coils of wire to create an electric current. The current is then regulated and passed through a voltage regulator to ensure it is consistent and safe for use. Generators are essential for powering electrical appliances and systems in homes, businesses, and other facilities. The basics of generator work involve understanding the type of generator being used, the voltage and wattage requirements of the appliance or system, and the safety precautions necessary to operate the generator.

Conclusion

Generators are an invaluable tool for powering your home in the event of a power outage or in remote locations. Learning the basics of generator work, including fuel types, power ratings, and proper maintenance, is essential to ensuring that your generator runs smoothly and safely. With regular maintenance and proper use, a generator can provide reliable power for many years, keeping your home and your family safe and comfortable.